Power Flame will design and construct your burner management system and integrate it with your selected operating components. The result is a factory tested combustion/management package with single source responsibility.

An outline of basic operating requirements will produce a computer-generated design that will meet state-of-the-art in burner management system operations.

The Model DC-4-AS Sequence Overfire Draft Control monitors and controls either positive or negative combustion chamber environments. The standard system incorporates an adjustable starting draft, auto-open damper selector switch, low draft cutoff with adjustable time delay, controller/pressure LED readout and damper actuator assembly. Optional features include stack temperature monitor with digital LED display and linear damper actuator assembly.

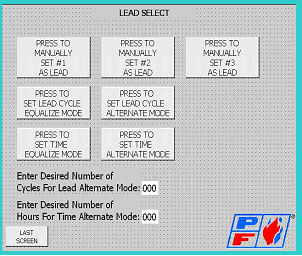

Power Flame’s packaged systems provide lead/lag operation for multiple burner installations. These vary in complexity from the relatively simple, multi-pressure/temperature controlled configurations – Type SL, LL, and ML – To the more sophisticated, single pressure/temperature, proportioning time response systems Type PL.

All lead/lag control systems can be integrated into the master burner management control panels, packaged separately for individual wall/surface mounting or, where space is available, incorporated into the integral burner mounted control panel.

Power Flame also offers 508A Industrial and Hazardous Location Control Panels