CONTROLS

POWER FLAME DIRECTOR SCS

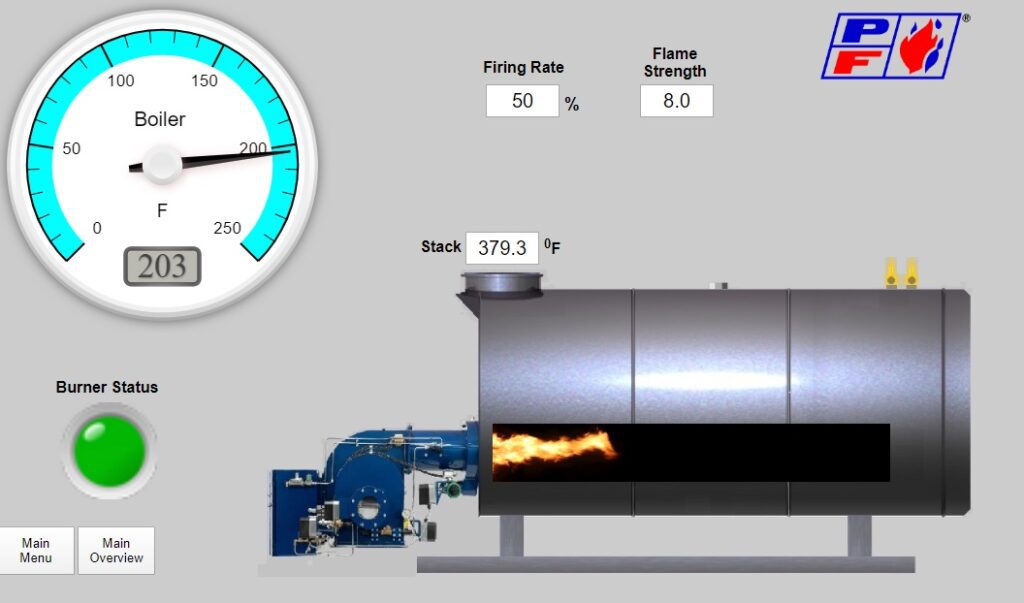

Power Flame’s Director® SCS offers high-quality graphic annunciation of critical burner functions at a most affordable price. The 10” Display provides a view of operating status on a lighted graphic identical to burner system features. The Director® SCS is a packaged Burner Management System, which includes annunciation, that removes service guesswork by graphically reporting system status.

The Director SCS, combined with the Honeywell slate linkage less burner control provides the best technology solution with a solidly proven approach to boiler management and interface to operators and higher-level systems. The flexibility of the system allows for custom design and functionality specific to customer needs and requirements. The scope of supervision can go beyond the burner, encompassing the boiler, feedwater system, etc.

The solid base of the system is the Honeywell slate burner module, working hand in hand with the fuel air ratio module. Major functions of the slate include:

USER CONFIGURABLE THRESHOLD ALARMS:

All Director SCSs have user configurable threshold alarms. Values can be set to warn of impending problems before the problem can cause a complete shutdown of the boiler. User configurable alarms include; Flame Signal, Flue Gas Temperature, High and Low O2 Level, Feed Water Rate of Change, High and Low PV. Note: Some alarms require specific hardware options and may not be available on all system configurations.

OPTIONAL USER CONFIGURABLE AND SCALABLE ADDITIONAL ANALOG INPUTS:

With the optional analog input cards the Director SCS can display a variety of process values such as steam flow, gas flow, oil flow, feed water flow, TDS and economizer parameters.

INTERFACE TO BMS & MPS:

The Director SCS is capable of interfacing with higher level Building Management Systems and Manufacturing Process Systems via optional Modbus, BACnet/IP, Modbus TCP, IP.

INTRANET AND INTERNET MONITORING:

The Director SCS can be viewed on Internet Explorer over an Intranet network internal to a building or over the Internet around the world. To use the Internet feature a router address option is available on the Director SCS. Router and firewall settings will be required to allow Internet access.

IP ADDRESSING:

The IP address of the Director SCS can be set manual or can be assigned by a DHCP server. The router IP address can also be set to allow access to the Director SCS over a networked DSL router.

For burner parts, wiring diagrams, and service related issues, please contact our Product Support: 620-820-8301.